|

Pan-Pioneer

promote our variety of portal type payoff / takeup

stands for our customer

with proud. Starting from loading bobbin size of 200mm up to

4000mm diameter reels , pan-pioneer offer the most suitable

for different applications.

The

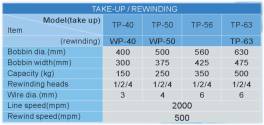

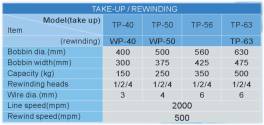

first one is the traditional and popular model : shaft-less

payoff take / take up stand. Or bare wire rewinding cable and wire machine.

The advantage of this model can be seen the simplicity of

design for easy operation and maintenance. You can useas

portal type payoff / takeup as for either wire drawing cable and wire machine

( with a dancer) or portal type payoff / takeup

tension-controlled payoff stand

for extrusion line. Simple design portal type

payoff / takeup means low cost , portal

type payoff / takeup for budget

buyers, this is one of the most suitable model for them. The

first one is the traditional and popular model : shaft-less

payoff take / take up stand. Or bare wire rewinding cable and wire machine.

The advantage of this model can be seen the simplicity of

design for easy operation and maintenance. You can useas

portal type payoff / takeup as for either wire drawing cable and wire machine

( with a dancer) or portal type payoff / takeup

tension-controlled payoff stand

for extrusion line. Simple design portal type

payoff / takeup means low cost , portal

type payoff / takeup for budget

buyers, this is one of the most suitable model for them.

The

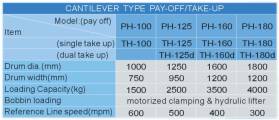

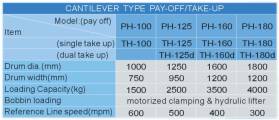

second one is what we called ˇ§cantileverˇ¨ type payoff /

takeup stand, Just like its name, the reel is lift up by a

hydraulic system which is fully automatic operation since the

cantilever will lift-up / put-down the reel by a

portal

type payoff / takeup hydraulic

system and clamping by a motor driven system For instance , it

will lift-up / put-down the clamped reel until to its up-most

/ ground position while the reel is empty / fully-loaded . The

movement of this cable and wire machine is limited by a positioning sensing

system for protection and security . A 4-way joystick is

equipped for easy operation. Traversing speed is adjustable

automatically corresponding to the takeup rotating speed. This

model is most suitable for ˇ§mid-rangeˇ¨ reel applications .

The most suitable range is from 800mm up to 2000mm reel with

maximum 6 ton lift weight for standard (can increase the lift

weight if necessary). The

second one is what we called ˇ§cantileverˇ¨ type payoff /

takeup stand, Just like its name, the reel is lift up by a

hydraulic system which is fully automatic operation since the

cantilever will lift-up / put-down the reel by a

portal

type payoff / takeup hydraulic

system and clamping by a motor driven system For instance , it

will lift-up / put-down the clamped reel until to its up-most

/ ground position while the reel is empty / fully-loaded . The

movement of this cable and wire machine is limited by a positioning sensing

system for protection and security . A 4-way joystick is

equipped for easy operation. Traversing speed is adjustable

automatically corresponding to the takeup rotating speed. This

model is most suitable for ˇ§mid-rangeˇ¨ reel applications .

The most suitable range is from 800mm up to 2000mm reel with

maximum 6 ton lift weight for standard (can increase the lift

weight if necessary).

For

a non-stop operation which is manufacturer favorite , you need

utilized on of the

following models For

a non-stop operation which is manufacturer favorite , you need

utilized on of the

following models

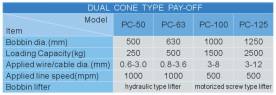

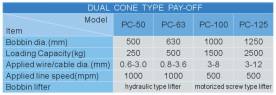

ˇ§More

stop means more scribe wastesˇ¨ .This is manufacturer most

unlikely to see, for extrusion line , especially. For high

speed ,mass production condition, a dual-cone payoff is the

best choice for small bare-stranded wires as a payoff device

of an extrusion line. By using this device , the extrusion can

be fed core conductor which is rewound in bobbins continuous

by connecting the end of one bobbin wire to the beginning of

the other bobbin. By doing this , Cone type payoff stand can

be regarded as a non-stop single wire provider which a normal

single wire payoff cannot do . The other application dual cone

payoff stand can reach is acted like two sets of normal single

wire payoff stands which can feed two wires to extrusion line

at the same time for some applications, such as power cores,

control cables , etc. ˇ§More

stop means more scribe wastesˇ¨ .This is manufacturer most

unlikely to see, for extrusion line , especially. For high

speed ,mass production condition, a dual-cone payoff is the

best choice for small bare-stranded wires as a payoff device

of an extrusion line. By using this device , the extrusion can

be fed core conductor which is rewound in bobbins continuous

by connecting the end of one bobbin wire to the beginning of

the other bobbin. By doing this , Cone type payoff stand can

be regarded as a non-stop single wire provider which a normal

single wire payoff cannot do . The other application dual cone

payoff stand can reach is acted like two sets of normal single

wire payoff stands which can feed two wires to extrusion line

at the same time for some applications, such as power cores,

control cables , etc.

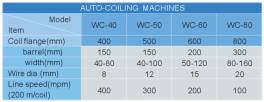

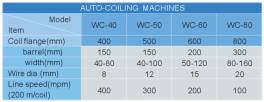

Continuous

payoff system need a non-stop takeup stand to match the

maximum performance . The first choice is auto coiling cable and wire machine. This

cable and wire machine is for final products packaging. By

using autocoiler , operator can rewind the cable into

ˇ§coilsˇ¨ for market selling. Operator can set the length /

weight of each coil he want to make and autocoiler will take

care the rest of the job. Since it is a non-stop takeup stand,

one operator is need for wrapping / binding each coming

coiler( standard model) or let the cable and wire machine do all the job ,

even put it on the palette itself ( fully automatic model) for

labor-cost saving.

Autocoiling cable and wire machine are one of the most popular coiling

making cable and wire machine in Asia. Continuous

payoff system need a non-stop takeup stand to match the

maximum performance . The first choice is auto coiling cable and wire machine. This

cable and wire machine is for final products packaging. By

using autocoiler , operator can rewind the cable into

ˇ§coilsˇ¨ for market selling. Operator can set the length /

weight of each coil he want to make and autocoiler will take

care the rest of the job. Since it is a non-stop takeup stand,

one operator is need for wrapping / binding each coming

coiler( standard model) or let the cable and wire machine do all the job ,

even put it on the palette itself ( fully automatic model) for

labor-cost saving.

Autocoiling cable and wire machine are one of the most popular coiling

making cable and wire machine in Asia.

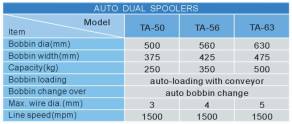

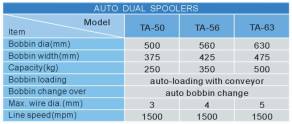

The alternative of the non-stop takeup stand is Dual

spooler cable and wire machine

with auto-change functionality. Not like

autocoiler showing above ,this cable and wire machine

is rewind the product

on ˇ§reelsˇ¨ therefore it is most suitable for intermediate

process of cable production process. This model is equipped

with a auto-change over system which can change over the

takeup reels while another is to it full length. Except this

functionality , Dual spooler is equipped with a caterpillar at

each side of cable and wire machine for loading/unloading reels during

operation. To synchronization of inline real-time operation ,

this cable and wire machine utilize special communication protocol named

ˇ§Mod Busˇ¨ which is a high speed and industrial standard

protocol , PLC communicate with the driving motor device (such

as DC motor drive or AC motor inverter)

for eliminating the noises which

traditional analogue signal suffer from..

The alternative of the non-stop takeup stand is Dual

spooler cable and wire machine

with auto-change functionality. Not like

autocoiler showing above ,this cable and wire machine

is rewind the product

on ˇ§reelsˇ¨ therefore it is most suitable for intermediate

process of cable production process. This model is equipped

with a auto-change over system which can change over the

takeup reels while another is to it full length. Except this

functionality , Dual spooler is equipped with a caterpillar at

each side of cable and wire machine for loading/unloading reels during

operation. To synchronization of inline real-time operation ,

this cable and wire machine utilize special communication protocol named

ˇ§Mod Busˇ¨ which is a high speed and industrial standard

protocol , PLC communicate with the driving motor device (such

as DC motor drive or AC motor inverter)

for eliminating the noises which

traditional analogue signal suffer from..

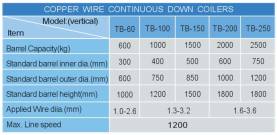

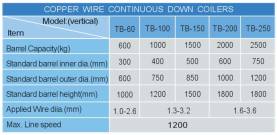

The

other commonly used non-stop takeup stand is Static coiler.

For High capacity load and the convenience for the following

process. This is the best choice for bare wire (copper wire

especially) manufacturing. The

other commonly used non-stop takeup stand is Static coiler.

For High capacity load and the convenience for the following

process. This is the best choice for bare wire (copper wire

especially) manufacturing.

Pan-Pioneer

Static coiler is equipped with a conveyor which can load 3

baskets at the same time, one basket is fully loaded and

another is during operation and the last one is a empty for

standby. This model is fully automatic with a length counter,

Operators no need to standby beside this cable and wire machine

for basket

change over , when the basket has reached its full length (

set by operator) , a special device will hold the dropping

wire temporarily until the basket change-over is complete.

With this convenient tool, no need for operators standby for

this cable and wire machine. . Pan-Pioneer

Static coiler is equipped with a conveyor which can load 3

baskets at the same time, one basket is fully loaded and

another is during operation and the last one is a empty for

standby. This model is fully automatic with a length counter,

Operators no need to standby beside this cable and wire machine

for basket

change over , when the basket has reached its full length (

set by operator) , a special device will hold the dropping

wire temporarily until the basket change-over is complete.

With this convenient tool, no need for operators standby for

this cable and wire machine. .

.

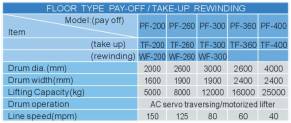

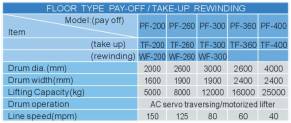

For

heavy loading cable takeup / payoff , portal (floor) type is

the most economic cost/performance devices for cable maker. For

heavy loading cable takeup / payoff , portal (floor) type is

the most economic cost/performance devices for cable maker.

Not

like the old-fashioning ˇ§Gate typeˇ¨ model , Portal takeup

/ payoff is like a successor with a much lower cost and refined design

then it predecessor

Compare

with its predecessor , portal model inherit all the

functionalities with amendments. For instance, portal type is

much low cost , save space , and still keeping the merits of

Gate type cable and wire machine. Equipped with a self-centering device in

front , Portal type cable and wire machine

can keep cable straight all the

time during operation. This merit is very important for ˇ§big

sizeˇ¨ cable for bending avoided. Compare

with its predecessor , portal model inherit all the

functionalities with amendments. For instance, portal type is

much low cost , save space , and still keeping the merits of

Gate type cable and wire machine. Equipped with a self-centering device in

front , Portal type cable and wire machine

can keep cable straight all the

time during operation. This merit is very important for ˇ§big

sizeˇ¨ cable for bending avoided.

Pan-Pioneer keep developing more advanced, higher

efficient , and more easy-operation devices for cable

industry. This photo shows our latest design : Dual head

auto-coiling cable and wire machine or Autocoiler. This

cable and wire machine is to eliminate the time

waste of traditional autocoiler during the ˇ§operation

circleˇ¨. For the traditional single head autocoiler ,

production speed is limited by the autocoiler rewinding speed

because it need about 10 secs plus rewinding time for one

complete operation circle, the 10 seconds become the bottle

neck of the whole production efficiency. That is why

Pan-Pioneer develop a two coiling head autocoiler to save the

precious ˇ§10ˇ¨ seconds, The proto type of this cable and wire machine

has

been complete already with a great success.

Pan-Pioneer keep developing more advanced, higher

efficient , and more easy-operation devices for cable

industry. This photo shows our latest design : Dual head

auto-coiling cable and wire machine or Autocoiler. This

cable and wire machine is to eliminate the time

waste of traditional autocoiler during the ˇ§operation

circleˇ¨. For the traditional single head autocoiler ,

production speed is limited by the autocoiler rewinding speed

because it need about 10 secs plus rewinding time for one

complete operation circle, the 10 seconds become the bottle

neck of the whole production efficiency. That is why

Pan-Pioneer develop a two coiling head autocoiler to save the

precious ˇ§10ˇ¨ seconds, The proto type of this cable and wire machine

has

been complete already with a great success.

Because

of the design concepts, this cable and wire machine

is for high speed (500mpm

and up) , 500M / coil application only. Using this cable and wire machine

as

a traditional autocoiler is a huge waste of your investment.

ˇ@

|